|

|

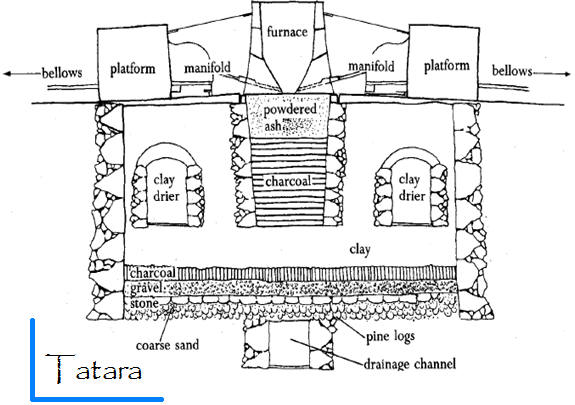

The traditional katana sword is fashioned only from the

purest steel, which the Japanese call tamahagane ("jewel steel"). Over

three days and three nights, smelters using ancient techniques shovel

roughly 25 tons of iron-bearing river sand and charcoal into the mouth

of a tatara, a rectangular clay furnace built specifically to produce a

single batch of tamahagane. Composed of carbon, the charcoal is as much

a key ingredient in steel as a source of fuel for the furnace. The

tatara will reach temperatures of up to 2,500 degrees F, reducing the

iron ore to steel and yielding about two tons of tamahagane. The highest

quality tamahagane can cost up to 50 times more than ordinary steel made

using modern methods.

|

|